Coordinator: Dr. Ausrine Bartasyte

ANR JCJC SIMI 4- Physique des milieux condensés et dilués

Stoichiometry, Structure and Strain Engineering in LiNbO3 and LiTaO3 thin films deposited by PI MOCVD

2013-2015

LiNbO3 (LN) and LiTaO3 (LT) are the two of the most important crystals, being the equivalent in the field of optics, nonlinear optics and optoelectronics to silicon in electronics. Thus, the studies about epitaxial ferroelectric LN and LT thin films are of great interest because of their potential application as elements in static random access memories, high dielectric constant capacitors, acoustic delay lines, microwave tunable devices, and optical waveguides.

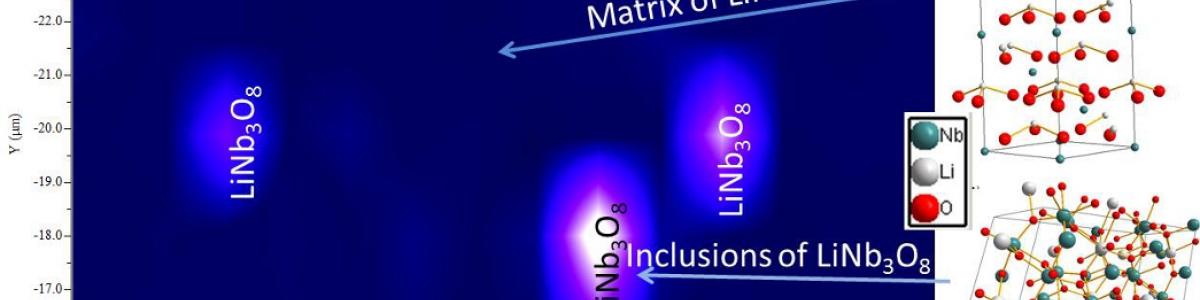

High epitaxial quality, single-domain (twin free) and stoichiometric LiNbO3 and LiTaO3 thin films

Although LiNbO3 and LiTaO3 films have been fabricated by different techniques, many electrical and electro-optical properties reported are not comparable for those of LiNbO3 and LiTaO3 single-crystals. Thus, the degradation of physical properties in thin films can be explained by the difficulty to control and to measure the Li concentration within the film. Moreover, the grain boundaries in polycrystalline films and twin structure in epitaxial ones lead to light scattering and large optical losses in waveguide devices fabricated from these films. Thus, high epitaxial quality, single-domain (twin free) and stoichiometric LN and LT thin films are needed.

The aims of this project are challenging:

-Deposition of stoichiometric LiNbO3 and LiTaO3 films (with 50 mol% of Li2O);

- Elimination of twins and ferroelectric domains in films with thicknesses = 1 µm;

-Tuning of the thermal expansion of thin films in order to reduce thermal frequency coefficient (TCF) – an important parameter in surface acoustic wave (SAW) devices.

Deposition of thin films by pulsed injection MOCVD and characterization by means of Raman spectroscopy and XRD

One of the most promising deposition methods for multicomponent films is pulsed injection MOCVD, providing digital deposition/composition control.

In order to optimize the Li content in the film, the method, able to measure Li concentration with precision of 0.1-0.2 %, is required. The indirect methods, used for the single crystals cannot be applied directly due to the presence of strain, size effects or other defects in the films, which influences also the structural, optical and other physical properties. Therefore, in this project the indirect methods for thin films, based on Curie temperature and Raman mode dampings , will be developed. Then, the Li concentration in films will be optimized varying the deposition parameters or by vapor transport equilibration. The twins and domains will be eliminated by studying the twin formation mechanisms, optimizing deposition and post-deposition conditions or by applying static electric field. The electrical and electro-optical properties of stoichiometric single-domain and twin-free films will be studied. The thermal expansion will be tuned by applying strain engineering and TCF of these films will be studied.