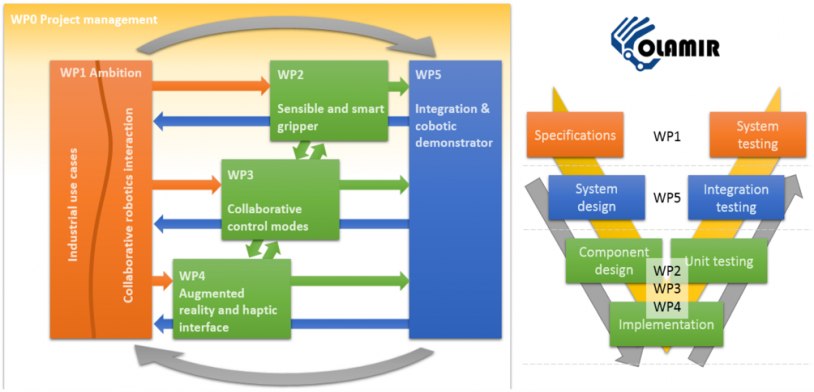

COLAMIR relies onto synergizing both scientific and industrial issues that will be addressed together during the project. Industrial partners will propose a micro-assembly platform from M6 and case study products to be assembled. Scientific challenges will be tackled to propose novel functionalities that will be progressively integrated within the platform. These works will feed the key main question of the project which consists in defining exactly how robot and human have to collaborate to successfully achieve micro-assembly tasks of complex micro products at the industrial scale. To achieve this goal, the following 5 Work packages are proposed below:

WP1: Ambition and collaborative strategy

Define how human and robot have to collaborate to perform robotic tasks on concrete industrial use cases from both technical and human acceptability point of view. COLAMIR’s ambition is to overcome the barrier drawn in the WPs figure, and validation of the platform and scientific development will be done in this WP.

WP2: Tactile and smart gripper

Develop the tactile sense of the robot through multi-DoF force sensing capabilities, and low level hybrid force-position control to ensure basic tasks such as stable grasping

WP3: Collaborative control modes

Definition of low-level control algorithm dedicated for the tactile sense chain of control. Developing high level control algorithm using the tactile sense to perform a set of tasks for the use cases assembly.

WP4: Augmented reality and haptic interface for micro-manufacturing

Create the optimal haptic tool for finger touch, allowing the user to manipulate (through the robot) microscopic objects “as easy as” for human scale ones. HMI tools to help operator driving the robot.

WP5: Integration and cobotic demonstrator

Build a preliminary platform enabling analysis of collaboration interest in use cases. Design and build of the final platform, continuously integrating project developments. Validation of robotic control/feedback.