I-SITE BFC

Building the Basic Blocks of Programmable Matter (B3PM)

Microelectromechanical systems (MEMS) have reached a position of design maturity and are therefore ready for the mass-production of micro-scale devices. Recent examples of mass-produced MEMS include accelerometers, inertial measurement unit (IMU) that are now integrated in airbag systems as well as in most of the recent smartphones or laptops, bubble ejection systems of inkjet printers or digital micro-mirror devices (DMD), a technology used for projection displays.

As can be seen from these examples, MEMS can be used either as single elements (accelerometers, IMU) or they can be grouped and can act together to reach a global goal (DMD). The latter is called distributed MEMS. The main interest of MEMS is that they can be mass-produced, which is true for single MEMS as well as for distributed ones (DiMEMS). It is therefore necessary to think of scalability up to millions of units when evoking distributed MEMS. Due to their small size, their low cost and the fact that they can be mass-produced, millions of units can be used in a very small space.

Distributed intelligent MEMS systems will be composed of thousands or even millions of systems which will raise new scientific challenges in micro-fabrication, integrated electronics, control and computer science.

The French National Research Agency (ANR)

Programmable Matter Project (ANR-16-CE33-0022)

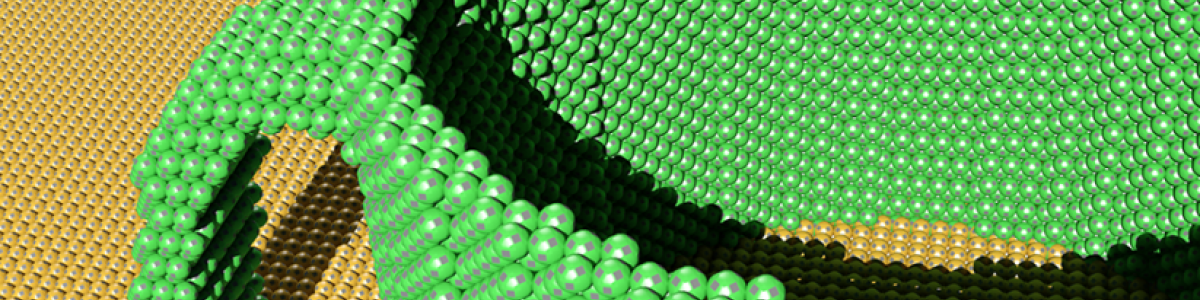

In this project, we will investigate a new smart system made from a hardware component and a software approach that will enable the creation of programmable matter. The hardware component is a mass-producible, sub-mm, MEMS, namely a micro-robot using computationally controlled actuators used for power distribution, communication, adhesion, and locomotion. The software approach aims to provide a language enabling scalable, real-time, efficient, expressive and at the same time safe programming of an ensemble of micro-robots and making this ensemble interacting with others communicating things through the IoT. Hardware and software for creating programmable matter

This research focuses on the main challenge to programmable matter: Scaling. For hardware the challenge is to scale down the size of the individual unit. For software the challenge is to scale up the number of elements that can be effectively controlled with a single, easy to understand program. Moreover, the simulation framework must scale up in the number of simulated micro-robots. We tackle the former by using a true 3-dimensional LSI/MEMS chip integration with deformable substrate as our main manufacturing method and a single effector, for all the necessary functionality of the unit. The latter is tackled creating Foxel a recursively scale-invariant functional shape description language implemented in a logic programming language, Meld, to create programs which are inherently concurrent, distributed, fault-tolerant, and also amenable to formal proofs.

This project is a follow-up of the Claytronics project initiated by Intel and Carnegie Mellon University and then co-leaded with FEMTO-ST.